1. Pre-Insulated Duct Panels: A Key Component in Modern HVAC Systems

In the ever-evolving world of heating, ventilation, and air conditioning (HVAC) systems, pre-insulated duct panels have emerged as a crucial element, revolutionizing the way we approach air distribution and energy efficiency. These panels are playing a pivotal role in enhancing the performance of HVAC systems across various sectors, from commercial buildings to residential complexes.

2. What are Pre-Insulated Duct Panels?

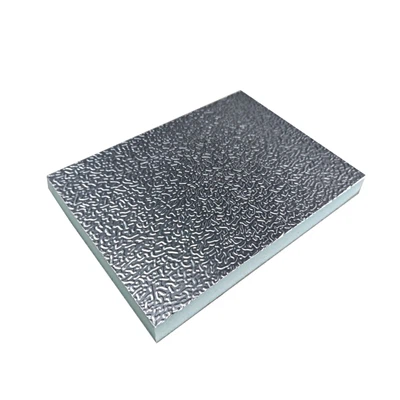

Pre-insulated duct panels are sandwich-structured materials. They typically feature a core of rigid closed-cell foam, such as polyurethane (PU), polyisocyanurate (PIR), or phenolic foam, which is then covered with aluminium facing on both sides. This construction makes them an innovative and highly efficient choice for HVAC applications.

3. Advantages Galore

3.1 Superior Thermal Insulation

One of the most significant advantages of pre-insulated duct panels is their exceptional thermal insulation properties. Materials like PU and PIR duct boards often have an impressively low thermal conductivity, sometimes as low as 0.020 W/m·K. This means that they can effectively minimize energy loss during the transportation of heated or cooled air through the ducts. As a result, HVAC systems become more energy-efficient, leading to reduced electricity consumption and lower operating costs.

3.2 Lightweight yet Durable

These panels are surprisingly lightweight, weighing just around 1.4 kg per square meter in some cases. This makes them easy to handle and install, reducing the labor required for HVAC ductwork installation. Despite their lightness, they are highly durable and can withstand a variety of environmental conditions, including temperature fluctuations and humidity.

3.3 Fire-Resistant Properties

Safety is a top concern in any building, and pre-insulated duct panels offer peace of mind in this regard. Many PIR panels, for example, are certified to meet strict fire standards such as the BS 476 fire standard. This makes them an ideal choice for both commercial and residential buildings where robust fire protection is essential.

3.4 Long-Lasting Performance

Pre-insulated duct panels are resistant to moisture, corrosion, and wear. This resistance ensures a long lifespan, reducing the need for frequent replacements and maintenance. Over time, this not only saves on maintenance costs but also minimizes material wastage, contributing to a more sustainable approach.

3.5 Improved Indoor Air Quality

The smooth surfaces of pre-insulated duct panels play a role in maintaining good indoor air quality. They minimize the accumulation of dust and microbial growth, ensuring that the air circulated in indoor spaces is clean and healthy.

4. Types of Pre-Insulated Duct Panels

4.1 Phenolic Duct Panels

Phenolic duct panels are made of phenolic insulation foam with either aluminum foil or galvanized iron sheets on both sides. They are popular in HVAC systems due to their energy-saving, eco-friendly, and fireproof properties. Their thermal conductivity ranges from 0.025 W/(mk) to 0.35 W/(mk), outperforming materials like rubber, plastic, and glass wool. Additionally, their unique connection method provides superior air tightness, which is nearly eight times that of galvanized steel ducts, resulting in significantly lower heat dissipation loss.

4.2 PU Duct Panels

PU ducts consist of polyurethane insulation foam with aluminum foil or galvanized iron sheets on their outer layers. The outer layer is often made of high-purity thin aluminum, while the middle layer is flame-retardant rigid polyurethane foam. These panels boast high strength, B1-level flame retardancy, waterproof and moisture-proof properties, and use pollution-free materials with stable performance.

4.3 PIR Duct Panels

PIR pre-insulated duct panels are made of polyisocyanurate insulation foam, usually with aluminum foil or galvanized iron sheets on both sides. PIR is a rigid foam insulation material formed by the reaction of isocyanate with polyether and a catalyst. It offers excellent flame retardant properties, low thermal conductivity, and good dimensional stability. Compared to phenolic ducts, PIR ducts provide environmental benefits, stable physical properties, good strength, and a long service life. In comparison to PU ducts, PIR ducts offer better fire resistance, as during ablation, a dense carbonized layer forms on the surface, hindering continuous burning and producing minimal smoke and irritation.

5. The Role in Sustainable Construction

As the world increasingly focuses on sustainable practices, pre-insulated duct panels are playing a vital role in the HVAC industry's contribution to environmental preservation. By improving the energy efficiency of HVAC systems, they help reduce carbon emissions associated with ductwork operations. Additionally, many of these panels are designed using recyclable materials, aligning with global initiatives for waste reduction and sustainable building practices.

In conclusion, pre-insulated duct panels are a game-changer in the HVAC industry. Their numerous advantages, diverse types, and contribution to sustainability make them an essential component for any modern HVAC system installation or upgrade. As technology continues to advance, we can expect even more innovative developments in the realm of pre-insulated duct panels, further enhancing the performance and efficiency of HVAC systems worldwide