15

2025

-

07

The Differences Between Galvanized Iron Duct Board And Composite Insulation Duct Board

Author:

Here is a comparison of the differences between galvanized iron duct board and composite

insulation duct board in tabular form:

| Comparison Items | Galvanized Iron Duct Board | Composite Insulation Duct Board |

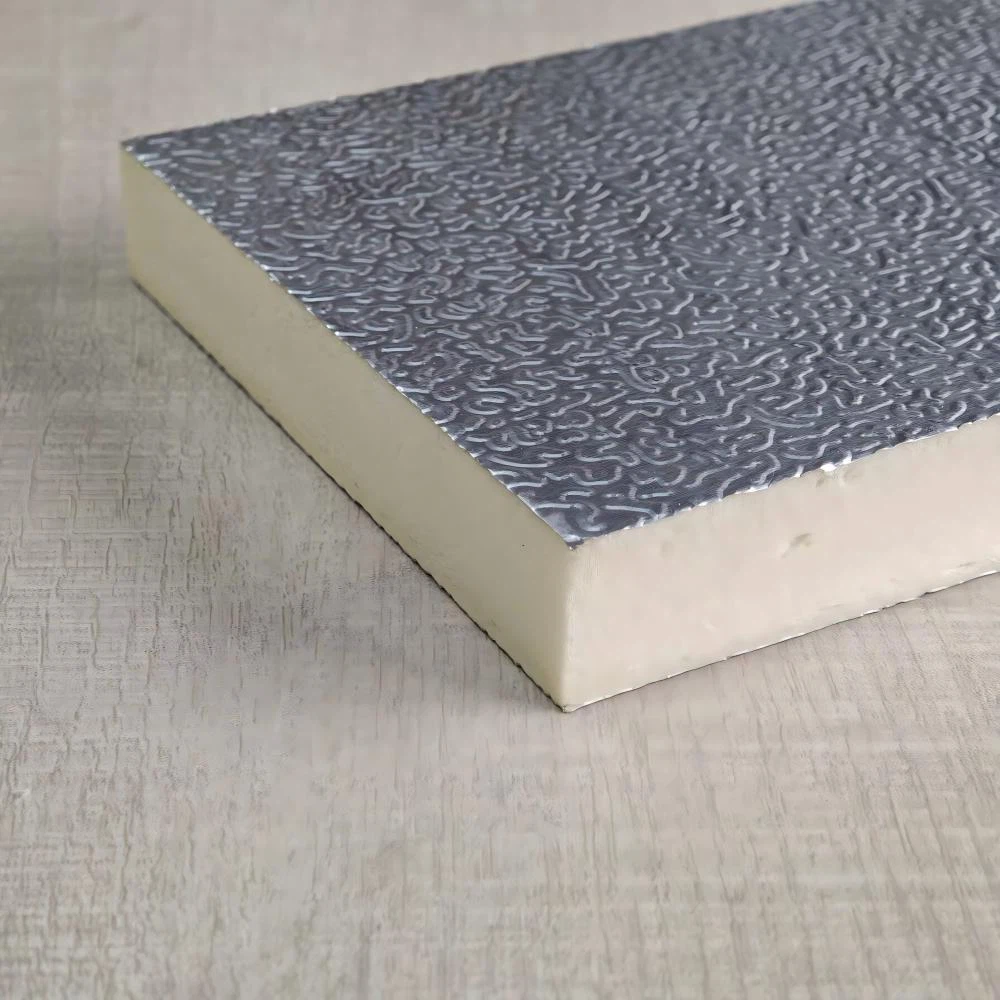

| Material Composition | Made of galvanized iron sheet, which is iron coated with a layer of zinc to prevent rust. | Consists of multiple layers, usually including an inner lining of fire - resistant and insulating material (such as glass wool, rock wool), a middle layer of insulating material, and an outer protective layer (such as aluminum - plastic composite film). |

| Thermal Insulation Performance | Has poor thermal insulation performance by itself. Heat can easily transfer through the metal, resulting in energy loss. | Has excellent thermal insulation performance. The multi - layer structure and the use of insulating materials can effectively reduce heat transfer, saving energy and maintaining indoor temperature stability. |

| Sound Insulation Performance | Does not have good sound insulation effect. It is easy to transmit sound, and the noise generated by the air flow inside the duct may affect the surrounding environment. | Generally has better sound insulation performance. The insulating material inside can absorb and block sound to a certain extent, reducing the noise of the |

| air conditioning system. | ||

| Fire Resistance | The galvanized iron sheet itself has certain fire resistance, but it is not a fire - proof material. In case of fire, it may deform and lose its function. | Usually has good fire resistance. The inner lining and insulating materials are often fire - resistant or flame - retardant materials, which can meet different fire - protection requirements. |

| Installation Complexity | The installation process is relatively complex. It requires professional tools and techniques for cutting, bending, and connecting. And it is heavy, which requires more labor and equipment for installation. | The installation is relatively simple. It is usually in the form of modular panels, which can be quickly installed and connected on site. It is lightweight, which is convenient for handling and installation, and can improve the installation efficiency. |

| Durability | It is prone to rust and corrosion in a humid environment or when the zinc coating is damaged, which will affect its service life. | Has good durability. The outer protective layer can prevent the intrusion of moisture and corrosive substances, and the internal insulating material has stable performance and is not easy to age. |

| Cost | The material cost of galvanized iron duct board is relatively low, but the installation cost is high due to the complexity of installation and the need for additional insulation measures. | The material cost is relatively high, but the overall cost may be lower considering the reduction of installation cost and energy - saving effect in the long term. |

Application Scenarios

PIR Pre-insulated Duct

Ideal Use Cases:

Commercial Buildings: Offices, hospitals, and malls (low noise, quick installation).

Data Centers: Reduces PUE by 15–20%.

Cleanrooms: Antimicrobial surfaces meet ISO 14644-1 Class 5 standards.

Outdoor Installations: Weather-resistant G.I. facing for harsh environments.

Limitations:

Not suitable for high-pressure systems (>2,000 Pa).

Requires fire-rated coatings in smoke control applications.

G.I. Duct

Ideal Use Cases:

Industrial Settings: Chemical plants, food processing (corrosion resistance).

High-Pressure Systems: Subways, airports (2,000–6,000 Pa).

Fire-Sensitive Areas: Smoke extraction systems (Class A fire rating).

Limitations:

High maintenance (annual corrosion checks + painting).

Poor energy efficiency without insulation.

28

2022-07

Application Of Blue Pre-Insulated Polyurethane (PU) Duct Board Featuring Aluminum Foil Rigid Foam

10

2022-01

A Key Component in Modern Pre-insulated Ductwork HVAC Systems

Xiamen UNT Duct Technology Co., Ltd.

Office : Room 209 No. 255 South Duiying Road, Jimei District, Xiamen City, Fujian Province, China

Factory : No 15 Building, South Yongding Industrial Park, Longyan City, Fujian Province, China