17

2025

-

05

Difference Of PU Foam Ductwork And Phenolic Duct Panels System

Author:

1.Fire - resistance performance

1.1Polyurethane duct panels: Polyurethane is a thermosetting plastic. After adding a flame - retardant, it becomes a self - extinguishing material. However, it has moderate fire resistance. In case of fire, it may produce more smoke and harmful gases compared to phenolic foam.

1.2Phenolic duct panels: Phenolic foam has excellent fire - resistance performance. It is highly resistant to flames and produces very low levels of smoke and toxic gases when exposed to high temperatures. It can meet the fire - grade A standard, which is very suitable for occasions where fire safety is of great concern.

2.Flame - retardant effect

2.1 Polyurethane duct panels: When polyurethane burns, a carbon deposit layer will be formed on the surface of its foam, which helps to isolate the underlying foam and prevent further combustion. But overall, its flame - retardant effect is not as good as that of phenolic duct panels.

2.2 Phenolic duct panels: Due to their chemical composition and structure, phenolic duct panels have an inherent flame - retardant property. They can effectively prevent the spread of fire and have a better flame - retardant effect.

3. Thermal conductivity

3.1 Polyurethane duct panels: The thermal conductivity of polyurethane is generally in the range of 0.018 - 0.024 W/(m·K). It has good thermal insulation performance and can effectively reduce heat transfer.

3.2 Phenolic duct panels: The thermal conductivity of phenolic foam is between 0.018 and 0.025 W/(m·K). Its thermal insulation performance is slightly better than that of polyurethane, which means it can maintain the indoor temperature more effectively and save energy.

4. Compressive strength

4.1 Polyurethane duct panels: Polyurethane duct panels have good compressive strength. Their closed - cell structure enables them to withstand a certain amount of pressure without significant deformation, which is beneficial to the long - term use of the duct system.

4.2 Phenolic duct panels: Phenolic duct panels also have relatively high compressive strength. Although their density is relatively low, their rigid foam structure endows them with good mechanical properties, which can meet the requirements of general duct installation and use.

In general, phenolic duct panels have obvious advantages in fire - resistance performance and flame - retardant effect, while both polyurethane and phenolic duct panels have good performance in thermal conductivity and compressive strength. The specific choice should be based on the actual needs of the project, such as the fire - safety requirements of the building and the energy - saving design goals.

28

2022-07

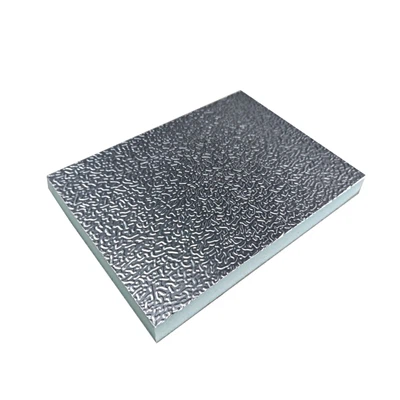

Application Of Blue Pre-Insulated Polyurethane (PU) Duct Board Featuring Aluminum Foil Rigid Foam

10

2022-01

A Key Component in Modern Pre-insulated Ductwork HVAC Systems

Xiamen UNT Duct Technology Co., Ltd.

Office : Room 209 No. 255 South Duiying Road, Jimei District, Xiamen City, Fujian Province, China

Factory : No 15 Building, South Yongding Industrial Park, Longyan City, Fujian Province, China