19

2025

-

05

PU Duct Panels And PIR Duct Panels Have The Following Differences

Author:

1. Composition:

PU duct panels: Made of polyurethane, which is synthesized by the reaction between a diisocyanate or a polymeric isocyanate containing two or more isocyanate groups and a macromolecular compound having active hydrogen atoms.

PIR duct panels: Made of polyisocyanurate foam. It is formed by the reaction of isocyanate with polyether under the action of a catalyst1. The ratio of polyol to isocyanate in PIR panels is different from that in PU panels, which affects their performance.

2. Insulation Properties:

PU duct panels: The thermal conductivity is generally 0.022 - 0.026 W/mK at 25 °C.

PIR duct panels: The thermal conductivity can be as low as 0.018 - 0.019 W/mK at 25 °C, which is lower than that of PU panels, so PIR panels have better thermal insulation performance.

3. Fire Resistance:

PU duct panels: Generally have lower fire resistance. They can ignite at lower temperatures and release more toxic gases when exposed to fire. Usually, they are of B3 grade, and can reach B2 grade by adding flame retardants.

PIR duct panels: Have better fire resistance properties. They can withstand higher temperatures before ignition and produce fewer toxic fumes when exposed to flames. Generally, they are of B2 grade, and can reach B1 grade by adjusting the concentration of the polyisocyanurate ring and other formulation techniques.

4. Moisture Resistance:

PU duct panels: Have moderate moisture resistance. The water absorption rate is 2.5% - 3%. They have a low tolerance for moisture, and water infiltration can lead to damage and a decrease in thermal insulation performance.

PIR duct panels: Have better moisture resistance. The water absorption rate can reach 0.9%. Their closed - cell structure makes them more resistant to moisture, which is suitable for areas with high humidity levels.

5. Density and Structural Properties:

PU duct panels: The density is generally 35 - 45 kg/m³, and the compressive strength is 150 - 200 kPa.

PIR duct panels: The density is generally 45 - 55 kg/m³, and the compressive strength is 250 - 300 kPa. PIR panels have a higher compressive strength, which means they can withstand higher loads and pressures without deformation.

6. Cost:

PU duct panels: Generally, they are less expensive than PIR duct panels, which may be more cost - effective for some applications with budget constraints.

PIR duct panels: Tend to be more expensive due to their superior insulation properties and fire resistance. However, their long - term energy savings and potential for reduced maintenance costs can offset the initial investment.

28

2022-07

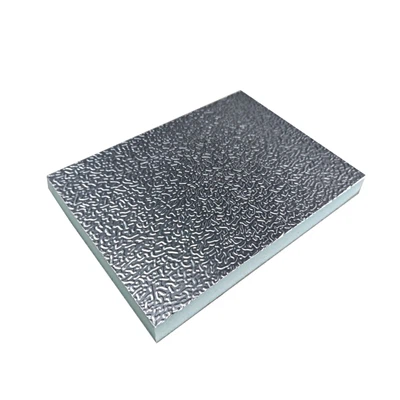

Application Of Blue Pre-Insulated Polyurethane (PU) Duct Board Featuring Aluminum Foil Rigid Foam

10

2022-01

A Key Component in Modern Pre-insulated Ductwork HVAC Systems

Xiamen UNT Duct Technology Co., Ltd.

Office : Room 209 No. 255 South Duiying Road, Jimei District, Xiamen City, Fujian Province, China

Factory : No 15 Building, South Yongding Industrial Park, Longyan City, Fujian Province, China